Custom molded rubber parts are an excellent solution for industries that require unique shapes, sizes, and functions in their products. The need for customized components increases as the industrial environment continues to evolve and become more specialized. These parts can be created using several processes, including dip molding, urethane foam molding, PVC molding, and rotational molding.

This blog post explores the advantages of several molding processes and the benefits of using custom-molded rubber parts for your industry.

Molding Processes for Custom Molded Rubber Parts

Custom molded rubber parts offer numerous benefits for industries that require unique shapes, sizes, and functions in their products. The following methods are all effective processes for creating custom molded rubber parts, each with advantages.

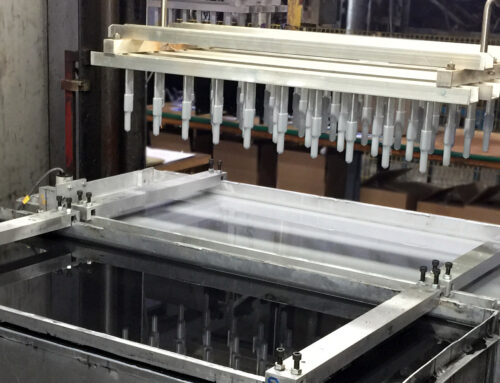

- Dip molding is used to create rubber parts with a uniform wall thickness. The process involves dipping a mold into a liquid polymer, allowing the polymer to adhere to the mold’s surface. Once the mold is removed, the polymer solidifies into a flexible rubber part. Dip molding is ideal for creating parts with simple shapes and uniform thicknesses.

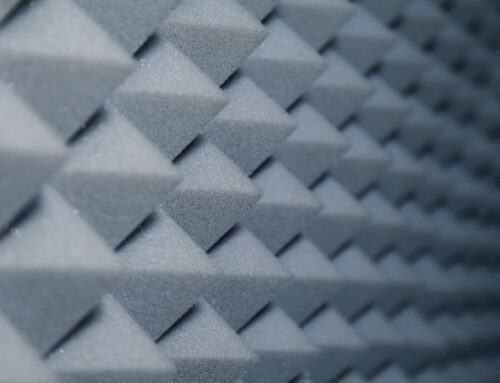

- Urethane foam molding is ideal for creating parts with complex shapes and intricate details. The method involves injecting a liquid urethane into a mold and allowing it to expand and solidify. This process produces rubber parts with a low density and high resilience.

- PVC molding creates rubber parts with a rigid and durable structure. The process involves heating and melting PVC pellets and injecting them into a mold. Once the PVC has cooled and solidified, it forms a rigid, durable rubber part. PVC molding is ideal for creating parts that require high strength and durability.

- Rotational molding is a process used to create rubber parts with a hollow interior. The process involves heating a mold and rotating it around two axes while introducing liquid polymer into the mold. As the mold rotates, the polymer adheres to the surface, creating a solid rubber part with a hollow interior. Rotational molding is ideal for making parts with complex shapes and hollow interiors.

Benefits of Using Custom Molded Rubber Parts

Creating custom parts using any of the processes listed above offers a range of benefits, such as:

Improved Product Performance

Custom molded rubber parts are designed to fit the specific needs of your product, which means they are optimized for performance. Using bespoke rubber components ensures the products function as intended, providing reliable and consistent performance.

Enhanced Durability and Longevity

Custom molded rubber parts are made from high-quality materials selected for durability and longevity. These parts can withstand harsh environments, extreme temperatures, and heavy usage, providing long-lasting and reliable performance.

Improved Aesthetics

Custom molded rubber parts can be designed to match the aesthetic requirements of your product, providing a clean and polished appearance. Customization options include color, texture, and finishing, ensuring that the final product meets the desired aesthetic standards.

Increased Efficiency and Cost Savings

Using made-to-order rubber parts can increase efficiency and cost savings by eliminating the need for additional components or modifications. According to a study by the National Institute of Standards and Technology (NIST), a major cause of manufacturing costs and delays is the need for rework due to poorly fitting components.

The study found that poorly fitting components can cause up to 25% of all manufacturing problems, resulting in significant costs and time delays. Custom parts can be designed to fit precisely, eliminating these problems and reducing the delays and costs associated with rework, adjustments or modifications during assembly.

The Unique Advantage

Custom molded rubber parts benefit industries such as the military that require unique shapes, sizes, and functions in their products. Dip molding, urethane foam molding, PVC molding, and rotational molding are all effective processes for creating exclusive rubber designs, each with its capabilities.

At Midwest Rubber Company, we specialize in creating high-quality custom-molded rubber parts that meet the unique needs of our clients. Contact us today to learn how we can help you improve your products with custom-molded rubber parts.