The healthcare industry spends approximately $200 billion each year on medical devices, according to a recent medical journal article. The equipment purchased includes diagnostic and medical apparatus and supplies across a range of manufacturers and suppliers, many of which are considered physician preference items (PPIs).

Numerous popular PPIs are products made using the process of dip molding, such as:

- Nasal and perfusion cannulas and endotracheal tubes

- Stethoscope Tubing

- Y-Connectors

- Catheter balloons and enema tips.

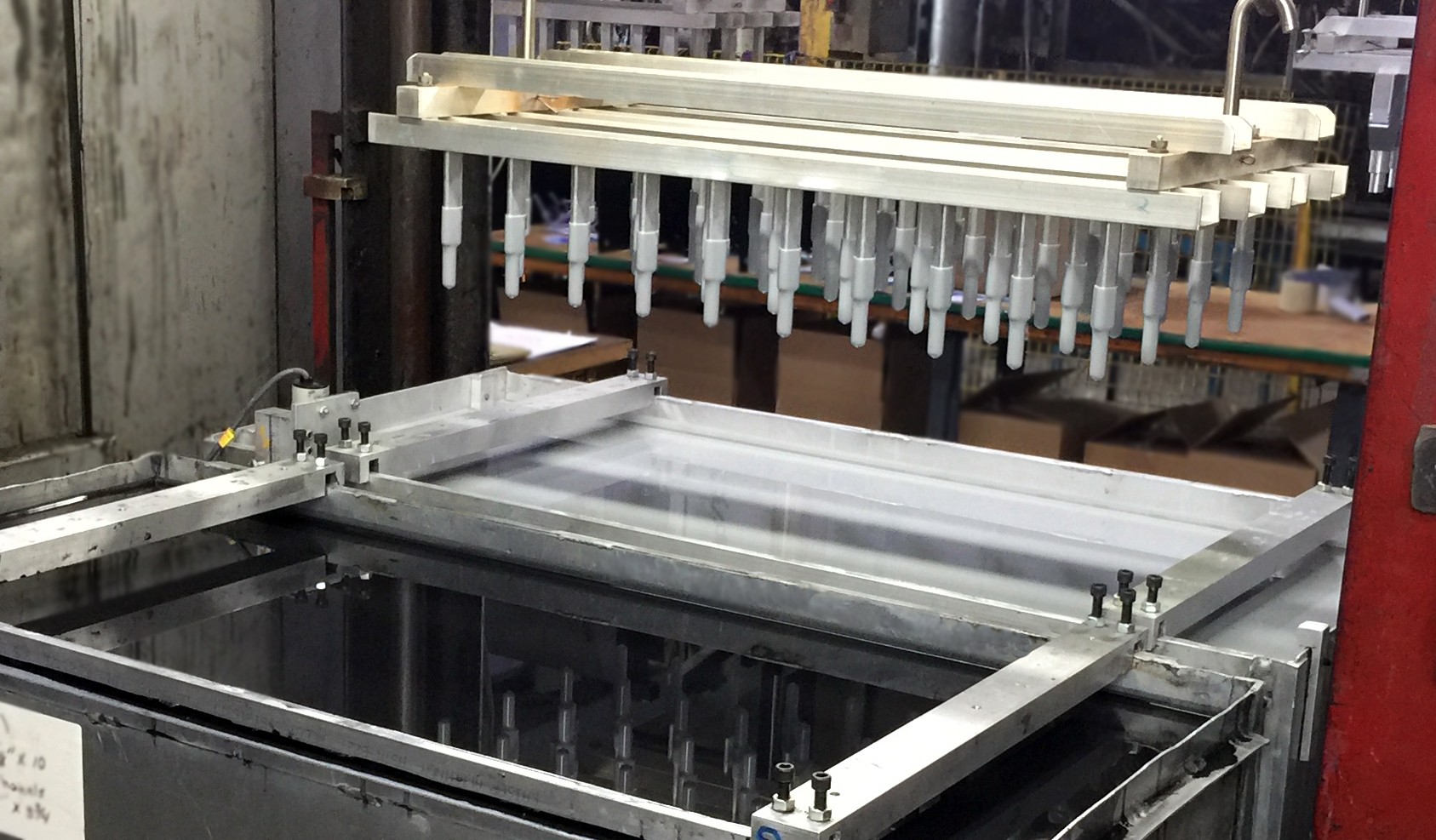

How Dip Molding Works

Dip molding is a simple, low-cost process used to create plastic or rubberized items with hollow interiors. This manufacturing method, which has been in use for many years, begins with a single-piece form that has a core but no cavity. The form (or mold) is submerged in a bath of heated material such as latex, neoprene, natural rubber, polyvinyl chloride (PVC), or urethane.

Once the required coating is thick enough, the material is polymerized or solidified using several appropriate methods. After that, the formed object can be removed from the mold, cooled, and trimmed of any excess material.

Benefits of Dip Molding

Medical products made with this process offer multiple benefits for both physicians and their patients, including:

1. Flexibility

Flexible hollow tubing is used for various purposes in the medical environment, including intravenous medication delivery, tying off wounds, and restricting blood flow. The products need to be tough and resilient but flexible enough to use in complex knots.

2. Sanitization

It’s essential in a medical environment to protect patients from medical surface contamination and avoid transferring bacteria from one location to another. Items such as endotracheal tubes and catheters are used internally in human bodies, which means any contaminants on the product can be introduced into a patient’s system. This can have devastating effects on a patient’s health and recovery and contribute significantly to the spread of hospital-borne diseases.

Dip molded medical components contain antimicrobial additives that prevent bacteria from adhering and replicating on the surfaces. Additionally, materials used in dip molding are easy to sanitize and maintain in a sterile environment in cases where they are reused.

3. Disposability

One of the significant advantages of dip-molded products are they are mostly disposable. Single-use items are in high demand in medical environments because of the reduced risk of infection and the time saved by not having to sanitize and maintain them.

The Centers for Disease Control encourages the use of disposable medical items primarily because they offer minimal preparation and effort while improving patient safety.

4. Cost Control

Dip molded medical supplies offer a unique opportunity for cost control. Because these components are not intended for re-use, manufacturing is low in cost, and longevity is not a requirement.

Costs such as maintenance, sanitization, and repair are entirely eliminated, as is the need for a sterile storage environment. The items arrive from manufacturing in sterile packaging, and both the container and component are discarded safely after use.

A Reliable, Affordable Option

Dip molding offers a reliable, affordable way to produce essential medical equipment and supplies. This option helps medical manufacturers and facilities to manage costs effectively while simultaneously providing a safe, sanitary solution.

For more information on dip molding for manufacturing medical supplies, please contact us at 810.376.2085.