At Midwest Rubber Company, we appreciate when our customers call us with their variety of product challenges and requests. Our manufacturing toolkit contains an assemblage of processes and solutions that we utilize based on the goals and needs of our customers.

With every project, we begin by evaluating their situation to determine the most beneficial and cost-effective approach to solving it. In the midst of the manufacturing process, we enjoy collaborating with our customers and witnessing the successes of the final product and solution.

Today, let’s take a close look at our dip coating process.

What Is Dip Coating Exactly?

Dip coating’s earliest known product is the candle, which some attribute to the ancient Egyptians, while others credit the ancient Romans thousands of years later. Today, everyday items manufactured by dip coating are in categories such as plumbing, electronic, automotive, and medical products/components.

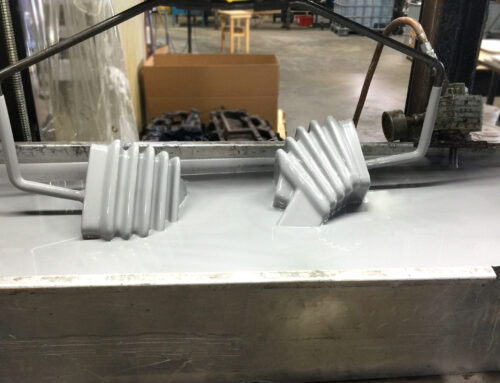

At Midwest Rubber Company, our dip coating process involves heating a part, dipping it into a PVC or rubber coating material (similar to dip molding), and then we heat it again to “set” the coating and ensure that it adheres to the metal part that it covers. We then withdraw the dipped object at a controlled speed, corresponding to the coating’s desired thickness.

How Is Dip Coating Used?

Dip coating wonderfully rounds off and soften edges and corners. Thus, it frequently is the chosen manufacturing process for handles and levers, tools, furniture, electrical insulation, outdoor play equipment, cushion covers, medical instruments, and many other products.

Why Is Dip Coating A Good Choice?

Dip coating is a preferred choice in that it:

- Provides an attractive finish that is pleasing to the eye and comfortable to the touch

- Protects the metal components beneath it from abrasion and corrosion

- Offers impact resistance

- Is available in a variety of colors, gloss levels and surface textures

- Enables thickness and hardness to be highly customized to suit the specific need

- In medical applications, seals up porosity, withstands frequent disinfecting and is soft to the touch, and helps keep medical equipment clean, safe and comfortable for patients and medical personnel.

When Is Dip Coating The Right Choice?

Dip coating is particularly useful for manufacturing products in the medical, automotive, consumer goods and electrical industries. It translates well from one product to another, whether to manufacture a transit chair armrest, exercise equipment, hand tools, or a cattle handling tool.

As the dip coating process requires precise control and a clean environment, Midwest Rubber Company handles this well as we have taken great pride in our quality of service for more than 60 years. When you have a product that may benefit from the dip coating process, feel free to contact us at Midwest Rubber Company, and we will develop a solution together!