Rubber has become an essential part of our lives, mainly because of its unique attributes. Durability, weather resistance, and the ability to mold it to almost any shape make it a valuable addition to all types of engineering. As of the end of 2020, the world used 1.1 million metric tons of rubber, of which three-quarters was used for automobile tires and tubes. The remaining rubber was used for a wide range of products manufactured using various methods, including dip molding.

What is Dip Molding?

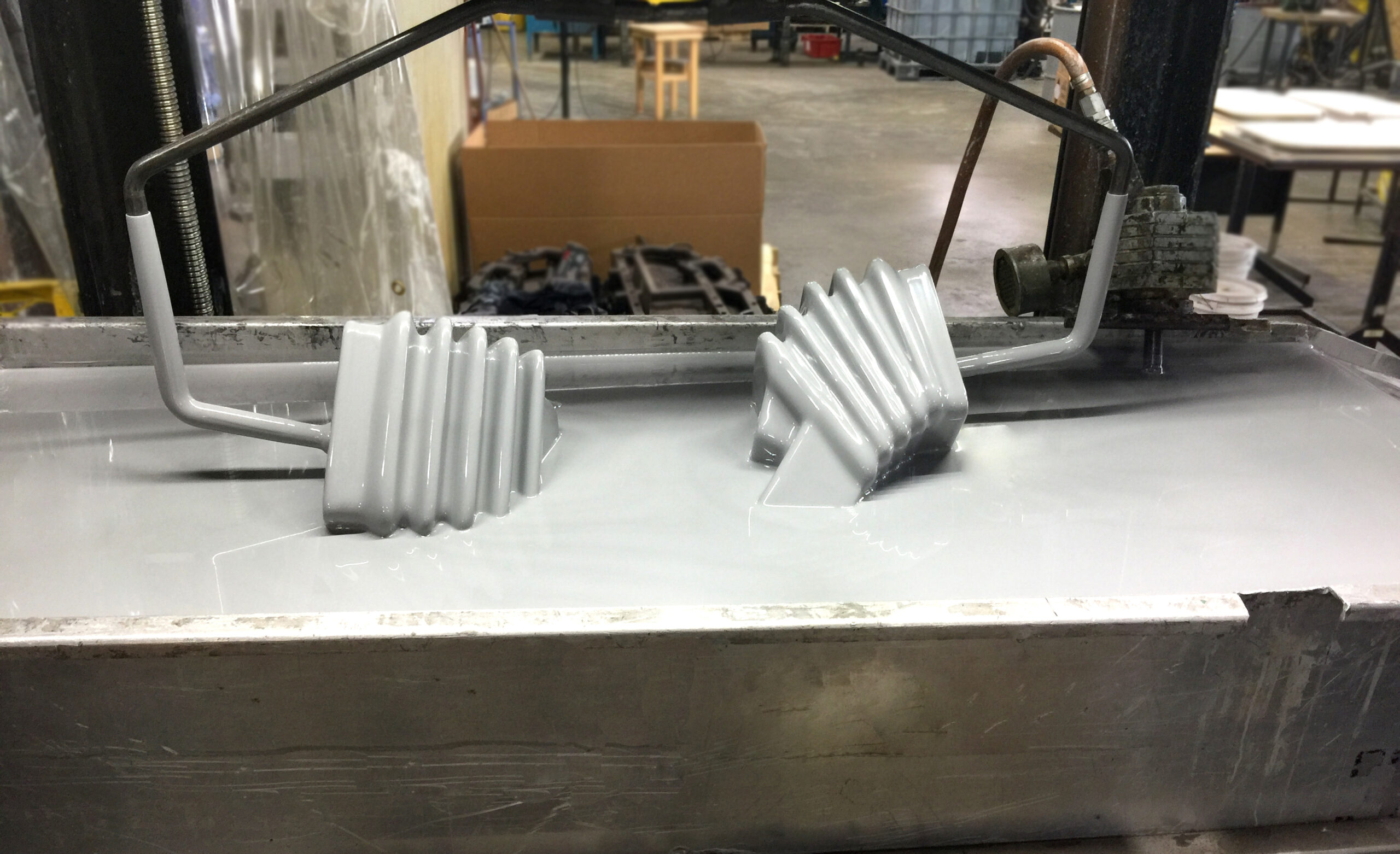

Dip molding is a method used to manufacture rubber parts with hollow interiors. It involves submerging a mold in a bath of heated rubber and then allowing it to cool. Once cooled, the hardened rubber exterior is removed from the mold. Because the mold fills the space inside the rubber, dip molding delivers products or parts that are hollow internally. In some cases, parts are dipped in rubber to create a coating, and molds are not required.

How Dip Molding is Used

Manufacturers in every industry use dip molding extensively. For example, common uses of this technique include producing automotive rubber parts such as bellows and seals for trucks and farm tractors. In the healthcare industry, dip molding is used to create durable, custom covers for metal components such as hospital bed rails. This makes it easier for patients to grip the rails comfortably and cushions the rails to prevent contact bruising. The rubber bar covers also protect and extend the life of the metal and can be replaced for a fraction of the cost of replacing the entire bed or bars.

How Dip Molding Works

Midwest Rubber Company (MRC) has been performing dip molding since the company’s earliest days and has reached a level of excellence that is second to none. Dip molding begins with choosing from our list of supported materials, which includes:

- Latex

- Neoprene

- Silicone

- Natural rubber

- Polyvinyl chloride

- Urethane

The mold is submerged in the rubber in controlled process conditions. After soaking for a predetermined length of time, the mold is removed and allowed to dry, or cured and cooled. The solid rubber shell is then separated from the mold, trimmed, and prepared for delivery.

Additional Benefits

In addition to the obvious benefits of protection and coverage, dip molding offers the extra advantage of being low in cost. This factor makes it an ideal choice for low-volume jobs in industries such as agriculture, although it can also be used for larger projects. The way items get dipped makes it possible to have different thicknesses without changing the mold, and even complex parts are easy to remove from the mold because of their elasticity.

For more information on dip molding and help choosing the most suitable option for your requirements, please click here to contact us.