Midwest Rubber Company is pleased to introduce you to slush molding, which is one of our many manufacturing methods. When our clients ask us to create an object that is largely cavernous, or concave, slush molding is our method of choice as it is an ideal technique for producing hollow objects.

Most of us do not realize the wide variety of hollow objects that we use in our daily life, and that slush molding may have manufactured them. This includes that pair of rubber rain boots in your closet, shoes of all types, and even toys. Many automotive products also are produced via this technique, such as protective skin coatings on headrests and arm rests, and leather look gear shift boots.

During our 74-year history, Midwest Rubber Company has appreciated using slush molding for a variety of reasons. It can accommodate both big and small product runs, which offers our clients greater flexibility. This manufacturing method also provides various options for customization, such as changing the appearance of the finished object by altering the form or thickness of the applied plastisol layer.

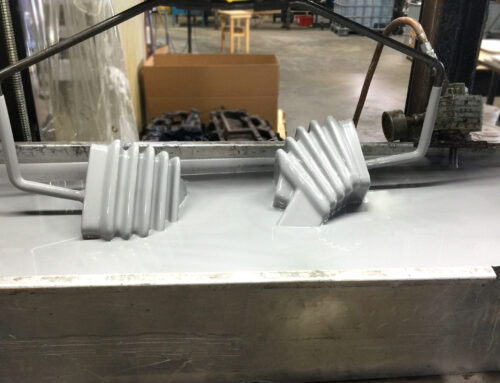

Like each of our processes, slush molding begins with a form. We start by heating an empty, hollow form, and then we coat it with a selected material for the project. Typically, we utilize a vinyl plastisol compound or vinyl powder compound.

This soft layer forms the basis of the finished item. Next, we turn the form upside down to remove excess compound, and we re-heat it to fuse the vinyl. After cooling it, we remove the completed product from the form.

At Midwest Rubber Company, we consider a well-made form as the most important part of a successful slush mold. A form of inferior quality with tiny holes on its surface will present pores on any part that is made using that form. To ensure quality, we quality-test each of our individual components before initiating the manufacturing process to ensure that our clients receive only the best slush molded parts.

If you’re interested in hearing more about our slush molding capabilities and any of Midwest Rubber Company’s other manufacturing methods, feel free to contact us. We will be happy to learn about your needs and to suggest the most effective solutions to accomplish your goals!