We are excited at Midwest Rubber Company to share another process that we utilize as part of our manufacturing of a wide variety of top-quality, highly-customized rubber and plastic parts for our clients from around the world. Our more than 60 years of working with our diverse clients enables us to satisfy them again and again.

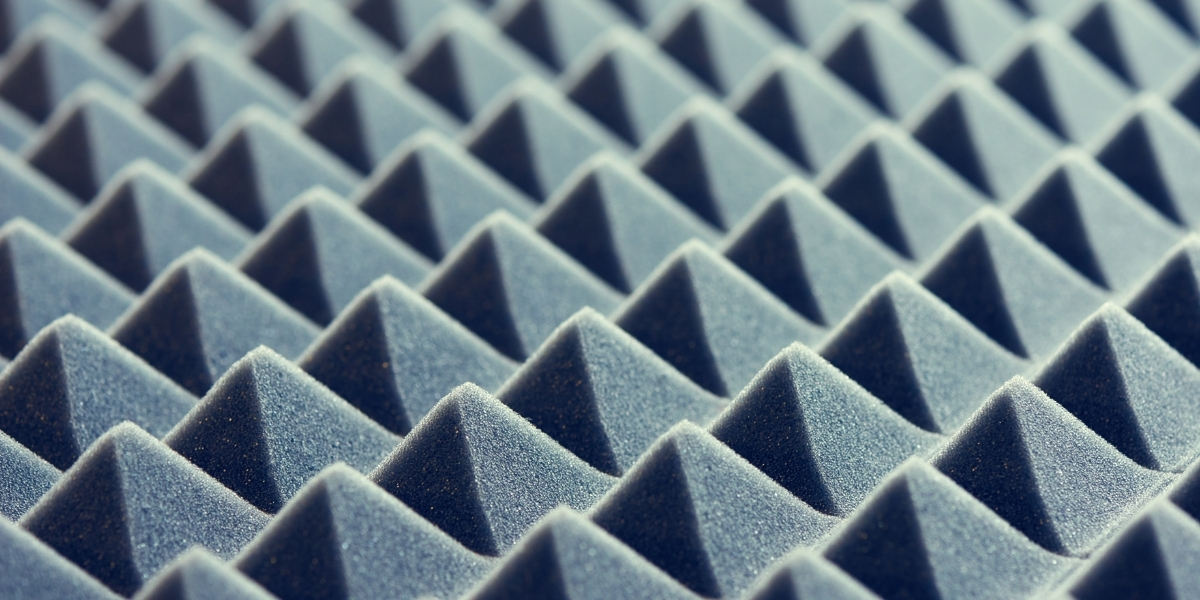

Have you ever looked at a mattress topper, couch cushion, or chair headrest and wondered what type of materials of which it was made? Chances are that it was made from polyurethane foam molding. A wide variety of possibilities exist with this excellent technique, including when our clients desire the production of soft, pliable objects or lightweight, rigid products.

At Midwest Rubber Company, we appreciate the highly-flexible polyurethane foam material, which can be fashioned into nearly any form for use in a wide variety of industries and products. Its benefits also include its resistance to stressors ranging from wear-and-tear, high temperatures, electricity, and many others.

Using foam rather than liquid differentiates the manufacturing process from other processes. Further, given that this material takes many shapes and forms, the process also varies. Thus, our industry utilizes common methods in the production process.

The process of working with urethane molding can be very delicate as foam is a feathery material that must be carefully controlled. However, it remains a popular method as it can be used to create a diverse array of products with applicability throughout numerous industries. In addition to consumer goods, polyurethane foam molding also is used to construct car seats, small machinery components, electronics cases, and many more products.

We are happy to share the foam molding manufacturing process. Upon meeting with our clients to acquire a thorough understanding of their project needs and expectations, we create a mold design that meets their exact specifications.

From there, we produce a mold, which usually is made of aluminum via this process, however certain difficult shapes require a mold of flexible silicone to allow easy removal of the finished product. When we prepare the mold, we mix together raw materials chosen specifically for the project along with a curative. When combined, they react together, resulting in a foamy solution that we pour into the form.

Colors and/or any other desired components are added, and depending on selected materials and the type of item we are producing, we apply heat or pressure. The filled mold then is allowed to sit until the foam solidifies to its final state. From there, we remove the object, and conduct finishing touches, such as adding a sealant or labels.

Midwest Rubber Company has decades of experience working with polyurethane foam molding and many other processes used in rubber and plastic manufacturing. We appreciate bringing our clients unique and effective solutions to meet their highly-specialized needs. Our many years of experience and innovation has made Midwest Rubber Company a well-established global leader in the rubber and plastic industry.

When you are ready to start on a polyurethane foam project, we are ready to make it happen! Contact Midwest Rubber Company today, and we will be happy to discuss the ways that we can serve you.