Rubber plays a vital role in so many industries around the world. From vehicles and production to the pharmaceutical industry, rubber helps to keep the world advancing and moving forward. One way that rubber usage in pharmaceutical industries plays a vital role is with rubber stoppers. These seemingly small items play a huge part in making sure that everything from vaccines to medications stay safe and uncontaminated. Learning the role of rubber stoppers in vials can help consumers appreciate the benefits of this equipment and also the advancements that are taking place in the industry on a daily basis.

Discover the many ways rubber stoppers in vials play a role in keeping patients safe and getting the medication from conception to realization in a sterile and controlled manner below.

What Do Rubber Stoppers Actually Do?

Rubber stoppers, also known as rubber bungs, are a vital part of keeping medication from becoming contaminated. These units help to seal a vial, medical tube or other container without actually displacing any of the liquid volume inside of the container. It helps to provide a tight, sterile seal to the unit so that the medication can be used in various settings.

Stoppers also help to prevent tampering with medication. Someone who is familiar with the rubber stoppers in vials can see if a medication has been tampered with before administering it to someone. This is crucial as seals that have been tampered with could have dangerous consequences for the end user.

These products also help to provide reusability to the vial when the proper techniques are utilized by the medical professionals. It allows multiple uses as long as the stopper is showing stability.

Rubber stoppers are used in various aspects of laboratory settings as well. They properly seal up vials after a blood draw while it is being run through various tests in the tube itself.

Types of Rubber Stoppers Used In Pharmaceuticals

When it comes to rubber stoppers in vials, there are several different types that are used in the industry. Each type has a different use and will be found in a variety of pharmaceutical settings.

Red rubber stoppers are typically found in a laboratory setting where the development of the medication would be taking place. The most common use for this type would be in a test tube where chemicals are being mixed together. This one is created with natural rubber like MWRCO produces.

Neoprene stoppers are created from a synthetic type of rubber that has a higher heat resistance over other types of materials. It is typically utilized in tubes or vials where petroleum-based oils are in use to help prevent the breakdown of the stopper itself.

Translucent stoppers can withstand a variety of temperatures and will be found in various tubes and vials.

Rubber stoppers come in a variety of sizes, shapes, and types of rubber to assist with the task they are used for. The rubber material and construction of the stopper will determine if it is used for high temperature needs or can withstand cold temperatures. For example, some medications such as insulin must be kept refrigerated. The stoppers used in these vials must be able to withstand the swings in temperature as a vial is put into use.

Benefits of Rubber Stoppers In Vials

The benefits of rubber bungs in the medical industry are numerous and provide advancements in technology for the future as well. When it comes to rubber usage in the pharmaceuticals industry, the benefits seem to be endless. Here’s a look at just a few of the benefits rubber stoppers can provide to those who have to use these types of medications.

Sterile environments when it comes to vials of medications are critical in making sure that cross contamination doesn’t take place. A rubber bung will do just that. It creates an environment where the medication in the vial is kept stable and sterile for multiple uses and patients.

Unfortunately, tampering can take place with medications. It is important that when a professional opens a vial, they know that it is safe to use with a patient. Including a rubber stopper as part of the vial helps to do just that. When a stopper has been tampered with it is clear to the familiar user.

Because the chemicals inside the vial need to be compatible with the seal, rubber offers a great way to work with a variety of chemicals. The many types of rubber provided by MWRCO helps to provide that protection while working hand-in-hand with the chemical inside the vial.

Using rubber for the stopper in a vial or tube makes it easy to access the contents with a needle or by extracting the stopper itself. The stoppers are also self-sealing due to the flexibility and nature of the rubber used in the unit.

This item also provides a level of safety to those in the medical field who are dealing with fluids from others. Because the rubber stopper fits firmly to the tube or vial, it prevents any leaks from happening. This keeps the substances where they need to be for proper processing.

Other Rubber Usage In The Pharmaceuticals Industry

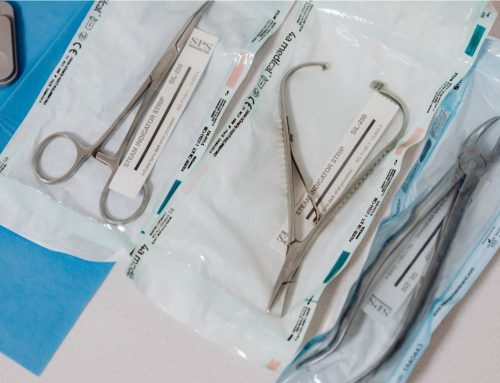

Rubber stoppers are just one of many ways that rubber usage in the pharmaceuticals industry has helped countless patients and medical personnel to do their jobs safely and effectively. There are actually many different ways that rubber has been used throughout the medical and pharmaceutical industries to help revolutionize care.

Other ways rubber can be used in the medial field includes:

- Medical tubing for delivery of medications

- Catheters

- Gaskets or O-rings on medical equipment

- Gloves for protection during procedures

- Drug therapy delivery devices

- Pacemakers

- And much more!

Rubber Stopper Production

MWRCO is a leader in the rubber production industry and provides high-quality results for their production. Producing rubber items for the medical and pharmaceutical industries requires strict adherence to safety protocols and guidelines. MWRCO produces a variety of rubber items such as natural rubber, silicone, and neoprene. These items must be produced in a highly controlled environment to ensure stability, durability and proper mixing.

Medical grade rubber is also put through strenuous testing to ensure the products ability to do the job it was created for. Whether it is rubber stoppers in vials or rubber usage in the pharmaceuticals industry, the testing will help to ensure it is ready for safe use. Some of the tests that the rubber is put through include both physical and chemical testing, functionality of the rubber stopper, and analysis of the rubber itself.

The advancements in rubber and technology help to keep the medical field moving forward with innovations and new ways of providing treatment and care to clients. Rubber offers a flexible, durable material for many different industries to help improve the care of patients and the safety of the medical professionals who take care of them.

For more information about rubber usage in the pharmaceuticals industry, contact MWRC for assistance. Our expertise and commitment to quality enable us to help you make the right rubber choices for your products.