It’s Midwest Rubber Company’s mission to create customized, unique solutions that can fix any design problem a client brings to us. But innovation is only part of what makes a product successful. We also make sure that everything we deliver is durable and reliable – that’s just one of the reasons we’ve been a supplier for the U.S. Army for more than 60 years.

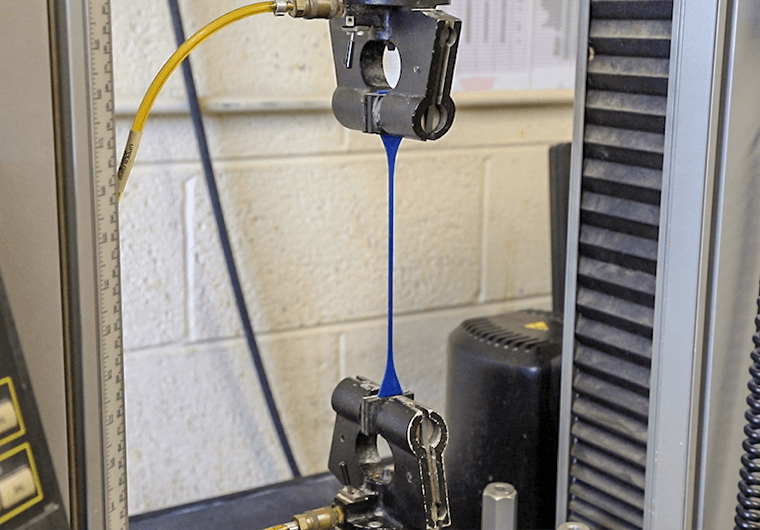

Our quality assurance begins at the earliest stage of development: with our staple resources. Once the proper material has been selected for a project, we test it to make sure it’s going to be strong and flexible enough to meet our clients’ needs. Throughout our construction process, Midwest Rubber Company’s talented employees constantly monitor the operation of our machinery, ensuring that it’s working just as it should so the resulting product is consistent.

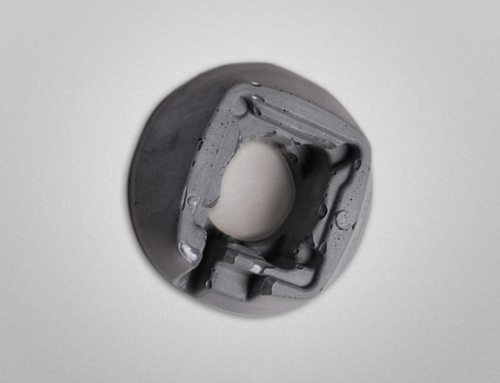

Our most meticulous testing is executed on the fully-formed object. It must be sturdy and reliable in build, while also flawlessly carrying out the function it was intended to fill. If Midwest Rubber Company or the customer is less than totally satisfied with how the end product looks, feels, or performs, we immediately start formulating a new solution. The capability we have for highly individualized manufacturing makes it easy for us to identify shortcomings in a product and change almost any aspect of it.

After we’ve corrected any deficiencies, the new version is assessed once again. Only when the item has received both Midwest Rubber and the client’s complete approval do we consider it finished. By then, it will have been subjected to multiple rigorous tests at every step of formation to confirm that our customers are receiving exactly what they’ve asked for.

The quality assurance procedures at Midwest Rubber Company have been evaluated by the International Automotive Task Force (IATF), a regulatory body that sets the bar for automotive parts and services. The IATF has awarded us with a certificate affirming that our practices are of the highest caliber. In addition, we have received two certificates from the ANSI-ASQ National Accreditation Board to indicate that Midwest Rubber Company’s management and environmental standards are in compliance with the International Organization for Standardization (ISO).

If you’re in need of a custom rubber component that will meet your specialized requirements, why not choose a company that tests for quality continually from start to finish? Midwest Rubber Company is ready to build a solution for you. Let’s get to work!