As healthcare continues to evolve, so does the technology behind the equipment used daily by medical professionals. Vacuum forming is a proven method that plays a critical role in shaping durable, hard-shelled components essential for medical devices. At Midwest Rubber Company, a proud U.S. manufacturer, we emphasize the value of producing high-quality, reliable products domestically, ensuring the excellence and safety healthcare providers and patients rely on.

How Vacuum Forming Works

Vacuum forming involves heating a sheet of plastic, silicone, rubber, PVC, or similar material to a forming temperature. Once heated, the material is applied to a single-surface mold, often made from wood or epoxy, and then pressed into place by a vacuum, which creates a precise fit. After the material cools, it is removed from the mold, trimmed, and finished. The result is a seamless, lightweight component that meets exact specifications, ready for a variety of healthcare applications.

Why Vacuum Forming is Ideal for Low-Volume Production

Unlike injection molding, which requires more complex tooling and higher upfront costs, vacuum forming is often more cost-effective for lower-volume production runs. It also offers shorter lead times, making it an ideal choice for customized healthcare applications where flexibility and quick turnaround are essential. This capability allows manufacturers to adapt products to specific patient needs without significant delays or costs.

Applications of Vacuum Forming in Healthcare

From enhancing patient comfort to maintaining sterile environments, vacuum-formed components are invaluable in medical settings. Here are some key applications:

- Wheelchair Seat Inserts: Vacuum-formed seat inserts distribute a patient’s weight evenly, helping prevent pressure sores, scoliosis, and hip problems, providing a custom solution for patient comfort and health.

- Calf Supports: Vacuum forming is used to create lightweight and durable calf supports for patients with mobility issues. These supports offer customized comfort and stability, helping improve patient outcomes during rehabilitation.

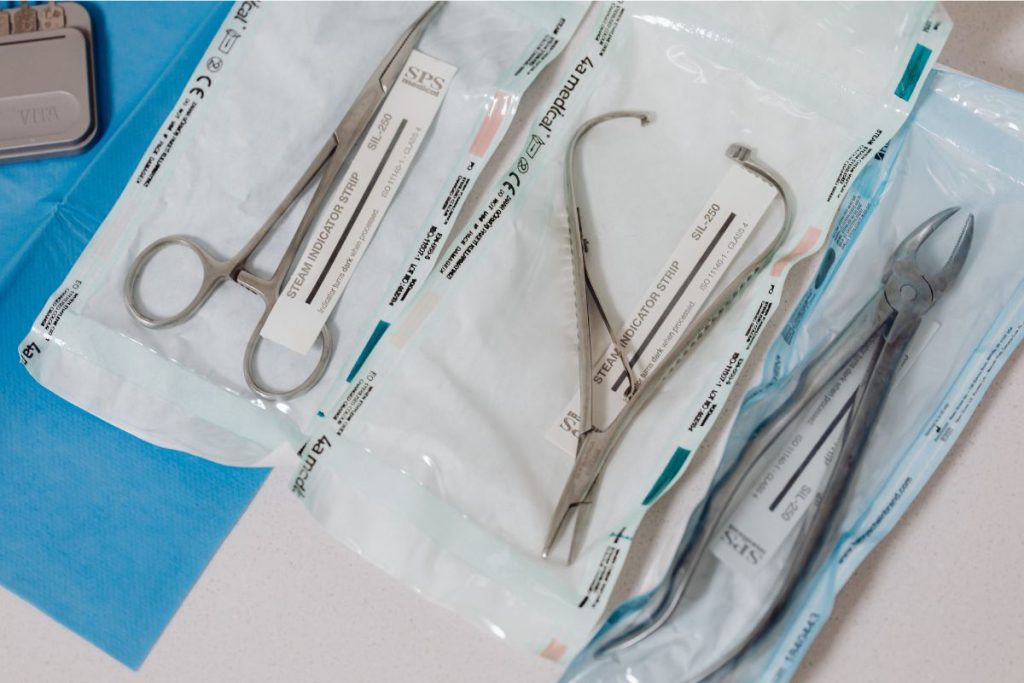

- Medical-Grade Packaging: Sterile, vacuum-formed packaging is a vital component of the healthcare supply chain. It serves as a hygienic barrier that safeguards items during shipping, handling, and storage, essential for disposable products that must remain contamination-free.

- Radiotherapy Masks: Patients receiving radiation treatment for brain, head, or neck cancer rely on custom-fitted vacuum-formed masks. These masks hold the head and neck completely still, protecting healthy tissue from unnecessary radiation exposure.

- Medical Instrument Enclosures: Sensitive medical devices require protective housing to maintain sterility and safeguard electronics. Vacuum-formed enclosures made from PVC, plastic, or rubber provide lightweight, cost-effective solutions for keeping these devices ready for immediate use.

- IV Fluid Bags: Vacuum forming is a key process in manufacturing sterile IV fluid bags. These bags, used for saline, medications, and blood transfusions, are a staple in hospital and home care settings. As demand for these essential items rises, vacuum forming helps meet the global need efficiently.

- MRI Equipment Components: MRI machines operate in strong magnetic fields, making metal impractical for their structure. Vacuum-formed parts offer an ideal non-metal alternative, contributing to the development of panels and components vital to MRI equipment.

- Disposable Medical Trays: Vacuum forming provides a lightweight, antimicrobial solution for medical trays. Once made from heavy metal, these trays are now single-use, reducing the risk of cross-contamination and providing healthcare providers with efficient, sterile options.

Why Buy American-Made Products?

Choosing U.S.-manufactured products like those from Midwest Rubber Company brings significant benefits. Our commitment to domestic production supports the local economy, creates jobs, and ensures products meet stringent quality and safety standards. Made-in-the-USA products also have reduced environmental impact due to shorter shipping distances and comply with U.S. labor and environmental regulations, providing a responsible and high-quality choice for healthcare providers.

Benefits of Vacuum Forming

For healthcare manufacturing, vacuum forming presents distinct advantages:

- Cost-Effectiveness for Low-Volume Runs: With lower tooling costs and faster setup times, vacuum forming is ideal for short-run production, prototyping, and customized medical devices, making it a strong alternative to injection molding for lower-volume needs.

- Material Versatility: Sheet materials for vacuum forming come in various colors, textures, and finishes, giving designers the flexibility to customize components for aesthetics and functionality.

- Customization and Adaptability: Vacuum forming can accommodate short production runs, allowing quick adaptations and modifications to meet specific needs without significant retooling costs.

- Lightweight and Durable Alternatives: Many parts once made of metal are now produced with lighter materials through vacuum forming, maintaining durability while enhancing ease of handling.

Midwest Rubber Company: Your Trusted U.S. Partner

As a leading American manufacturer, Midwest Rubber Company is dedicated to providing reliable, high-quality vacuum-formed components to the healthcare industry. We believe in the importance of U.S.-made products and the advantages they bring in terms of quality, safety, and economic impact. For more information on how our vacuum-forming capabilities can benefit your healthcare applications, please contact us at 810.376.2085.