Vacuum forming is a method of manufacturing thin, hard-shelled plastic or rubber components with minimal joints, contoured to specific shapes. A sheet of plastic, silicone, rubber, PVC or other rigid material is heated to a forming temperature. The material is then stretched and applied to a single-surface wooden or epoxy mold, after which it’s pressed against the mold by a vacuum. Once the material cools, it’s separated from the mold, excess material is trimmed away, and finishing takes place.

Vacuum Forming in Healthcare

Most companies that supply hospital and home care products use vacuum forming in medical devices. Some of these commonly-used products include:

- Vacuum-formed seat inserts for wheelchairs. For patients confined to wheelchairs, these inserts help distribute their weight evenly, preventing the development of scoliosis, bed sores, and hip problems.

- Medical-grade packaging. The largest market segment for medical packaging is for sterile, disposable products that are either lidded or non-lidded. This type of vacuum-formed packaging functions as a hygienic barrier while protecting and organizing the components during shipping, handling, and storage.

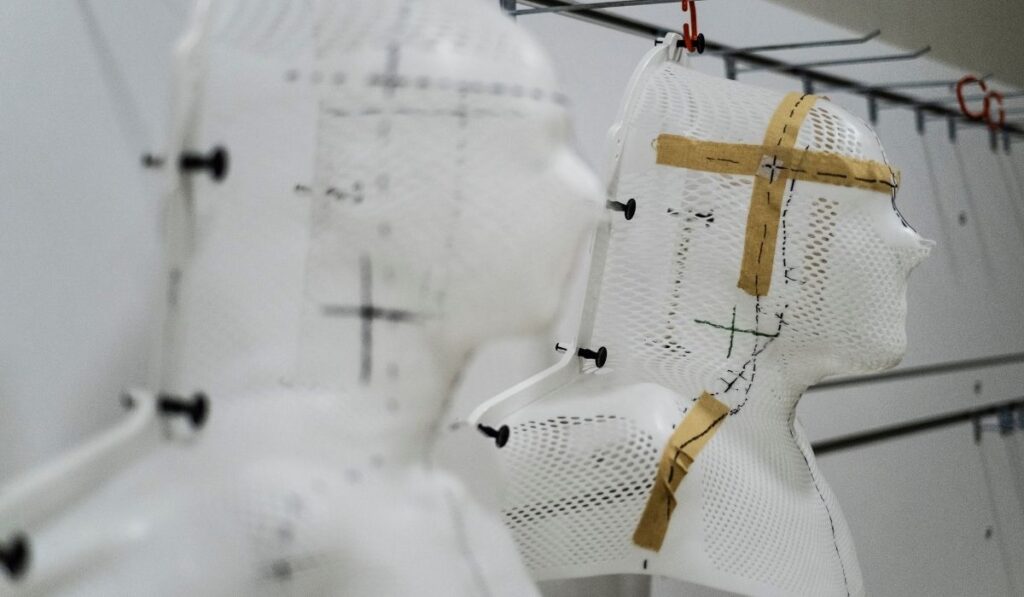

- Radiotherapy masks. Cancer patients who require radiation therapy to any part of the brain, head, or neck area must wear a rigid plastic mask during treatment. These masks are custom-made by vacuum-forming to hold the head and neck utterly immobile in exactly the right position, to avoid radiation damage to healthy tissue and organs.

- Dental castings and mouthguards. A dental cast, mold, or model is the positive reproduction of a patient’s teeth and the surrounding tissues obtained from a dental impression. Castings are used to make crowns, fixed bridges, and dentures. Vacuum forming also creates super-thin, lightweight mouthguards and whitening trays for use by dental patients at home.

- Medical instrument enclosures. Hospitals and practice offices often contain a myriad of electronic medical devices and equipment, which must be maintained in a sterile environment until needed. Steel, plastic, PVC, rubber, or fiberglass are often used for protective housings, and many of these enclosures can be manufactured cost-effectively using vacuum forming.

- IV fluid bags. Billions of IV fluid bags are used annually, and projections show the global market for these bags is likely to reach $6.057.60 million by 2030. This huge demand is fuelling the manufacture of the sterile, vacuum-formed bags used for dispensing saline, medication, blood transfusions, and other liquid substances in a hospital or home care environment.

- MRI equipment. Magnetic resonance imaging has become a popular, non-invasive diagnostic method used in hospitals across the globe. Due to the existence of a strong magnetic field, metal components are impractical in MRI equipment. Vacuum-forming offers the ideal method of developing panels and parts for use in the machinery and its housing.

- Medical trays. In the old days, medical trays were made from metal that was heavy to lift and had to be sterilized between uses. Now, vacuum forming provides a swift, cost-effective way to manufacture lightweight medical trays for every use. The inclusion of an antimicrobial additive enables them to remain sterile until used, after which they can be disposed of easily.

This list of vacuum-forming use cases is by no means exhaustive. The process can be adapted for manufacturing prosthetic limbs, storage options, and instrument housings inside medical vehicles, among others.

Benefits of Vacuum Forming

Vacuum forming offers multiple advantages, particularly for short-run or low-volume manufacturers of high-quality plastic components.

- Tooling costs are typically lower than other processes, and the turnaround time is faster. The resultant savings in cost and time make this a viable option for medical R&D (research and development) facilities, prototyping, and in some cases, long-term production.

- Sheet materials are available in a wide range of colors, thicknesses, and rigidity, and grains and textures can be applied to the exterior to give the appearance of a more expensive, grained injection tooling process.

- Highly detailed products can be manufactured in a wide range of sizes. Short product runs mean items can be adapted or customized according to customer needs. Quick changes are possible with minimal additional tooling or change costs.

- Products formerly manufactured from metal can now be produced in a much lighter weight.

- Anti-corrosion spraying is not required to maintain visually appealing aesthetics.

For more information on vacuum forming medical devices and the benefits to your company, please contact us at 810.376.2085.